Revised October 2002

MULTI-FLO WASTEWATER TREATMENT SYSTEMS

OWNER’S MANUAL

Consolidated Treatment Systems, Inc.

1501 Commerce Center Drive

Franklin, OH 45005

937-746-2727

www.multi-flo.com

THE MULTI-FLO ONSITE WASTEWATER TREATMENT SYSTEM

CONGRATULATIONS! You are the owner of a complete wastewater treatment system that

combines aeration and filtration in one compact unit. Your system is tested and certified under

NSF International, ANSI/NSF Standard 40, as a Class I system. The MULTI-FLO system meets

the needs for onsite wastewater treatment beyond the capabilities of septic tanks. Like all onsite

wastewater treatment alternatives, your MULTI-FLO unit must be operated and maintained in

accordance with the Manufacturer’s requirements and service provider’s instructions. When

properly operated and maintained, your unit will produce an effluent that meets all certification

requirements.

HOW DOES THE MULTI-FLO OPERATE?

One of the features of the MULTI-FLO is that the entire treatment process takes place within a

single tank. Wastewater flows into the tank. An aerator near the bottom draws air in and

disperses it. This process transfers oxygen throughout the system. The oxygen, which is

dissolved in the water, provides an environment conducive to the growth of aerobic bacteria.

These bacteria effectively consume the organic materials. Consider your MULTI-FLO a living

organism and treat it as such.

Another feature is the filter “socks,” which are suspended in the tank. The "socks" support

additional bacteria and strain all effluent before it leaves the unit. Solids are retained in the

system. There is no by-pass for solids.

IMPORTANT ITEMS TO REMEMBER

MULTI-FLO units have an initial break-in period of six-to-eight weeks, during which time

bacteria establish themselves in the unit. The development of these biological colonies occur

naturally with the addition of sanitary wastes, so we recommend you use all your plumbing

facilities in a normal manner from initial start-up. You may notice a tendency for the unit to

foam from laundry wastes during this period. This is normal, and it should cease by the sixth

week. You can help by using moderate amounts of low-sudsing biodegradable detergents.

MULTI-FLO units are designed to treat typical domestic wastewater. Flows from and materials

in garage catch basins, storm water drains, sumps, and the like will adversely affect MULTI-

FLO operation. Excessive amounts of cleaners, solvents, paints, greases, etc., will lead to a

failure and service calls.

The following of these simple rules will decrease or eliminate maintenance problems and

prolong the life and efficiency of your unit.

Maintain a service agreement with an authorized MULTI-FLO service provider.

Check that your unit’s access lid is securely tightened down.

Check the alarm by pressing the button to activate the light and buzzer on the audio-visual

alarm.

Call your service provider at the first sign of trouble.

Follow your service provider’s advice. He/she is trained to ensure that your unit operates at

its maximum efficiency.

Use low-sudsing, low phosphate biodegradable detergents.

Contact your service provider if the system is to be used intermittently or if extended periods

of non-use is anticipated.

Keep un-disposable items out of your system. Some examples include but are not limited to:

wet strength paper towels, disposable baby diapers, sanitary napkins, rubber and plastic

products, rags, grit, and coffee grounds.

Avoid discharging a water softener backwash into the system.

Avoid placing grease into your system. Excessive grease will bind the filter socks.

Do not pour solvents, paints, etc., into your system. These substances will harm the bacteria

and plug the filters.

Always keep your aerator running unless instructed otherwise by your service provider.

Do not service the unit yourself. Contact your service provider to maintain your MULTI-

FLO unit.

ALARM SYSTEM and ALARM CONDITION

Every MULTI-FLO unit comes equipped with an audio-visual alarm system. This alarm should

be mounted in a conspicuous location. If an abnormal condition develops, you will be notified

with a light and buzzer. Silence the buzzer by pressing the “silence” button on the alarm. If the

light should stay on, call your service provider.

Check your audio-visual alarm periodically by holding the “test” button for approximately 10-to-

12 seconds or until the light flashes and the buzzer sounds. Push the “Silence” button. Contact

your service provider if your “test” button fails to activate the alarm.

If your alarm goes off, there are several steps you can take to determine the possible nature of the

malfunction.

1. Is the alarm activated during a non-flow period, i.e., late at night, early morning? If

so, the probable cause is the aerator.

2. Is the alarm activated intermittently while washing clothes or taking a shower? If so,

filter failure (1–2 weeks) may be impending.

MAINTENANCE PROGRAM

YOUR MULTI-FLO UNIT REQUIRES PERIODIC SERVICING.

Maintenance of your MULTI-FLO is essential to ensure its proper operation and longevity.

During your initial two-year warranty, an authorized service representative will inspect your unit

at six-month intervals and make any necessary adjustments to the system. The only exception is

for the replacement of “out of warranty” and “physically abused” parts or abuse to the treatment

process. Moreover, this warranty will not cover other treatment and dispersal components and

devices, such as pre-tanks, drain fields, pump stations, and the like.

For continued service, your service provider will offer an annual service contract at the end of

the warranty. Please contact your service provider for details.

In the event a problem arises or service is required, refer to the unit’s data plate (located on the

alarm and access lid) or the service label for instructions on contacting your closest service

provider. Occasional pumping is required, due to accumulation of solids. The pumping cost

may not be covered under your maintenance and service program. If you need parts or service,

please contact the factory for the name of the service provider nearest you.

Your MULTI-FLO system is designed and intended to treat typical domestic wastewater (i.e.,

human bodily waste and liquid waste generated by the occupants of dwellings). To insure

optimum performance and longevity, do not discharge any type of non-residential wastewater or

other high-strength waste, including commercial food service waste, without contacting the

manufacturer to determine if this will be acceptable without additional treatment.

IMPORTANT: MULTI-FLO units must be installed and maintained in compliance with all state

and local laws and regulations. This includes compliance with all regulations concerning proper

effluent disposal and the pumping and disposal of solids and byproducts pumped from the unit.

MULTI-FLO WARRANTY DOES NOT COVER THE COST OF SERVICE CALLS, LABOR,

OR MATERIALS REQUIRED DUE TO THE FOLLOWING:

1. Misuse, abuse, or any repair or alteration performed by anyone other than authorized

MULTI-FLO personnel

2. Use of components other than authorized MULTI-FLO replacement components.

3. Non-wastewater flows caused by infiltration, storm water connections, leakage from

improperly maintained plumbing fixtures, water softener backwash, etc.

4. Failure to maintain electrical power to the treatment system in accordance with the

requirements of the Manufacturer or the authorized MULTI-FLO service provider.

5. Disposal into the MULTI-FLO of non-biodegradable materials (i.e., plastics, coffee

grounds, etc.) chemicals, solvents, grease, oil, paint, or any other substance, including

but not limited to medicines, metals, toxins, volatile substances, and the like that are

deleterious to the development and maintenance of the biological treatment process.

6. Short-term or daily wastewater flows to the MULTI-FLO that exceeds the unit’s

hydraulic or organic design capabilities.

7. Any usage contrary to MULTI-FLO owner’s manual and/or the MULTI-FLO

representative’s recommendations.

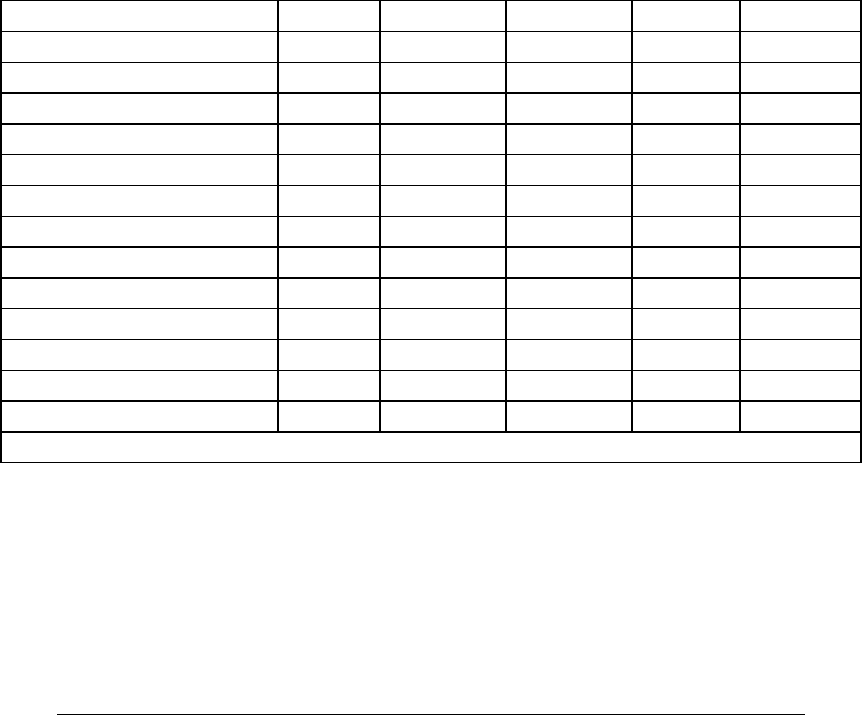

MULTI-FLO MODEL SPECIFICATIONS

Item FTB 0.5 FTB 0.6 FTB 0.75 FTB 1.0 FTB 1.5

Treatment (gal/day) 500 600 750 1000 1500

Volume (gal)l 500 600 750 1000 1500

CBOD (lb/day) 1.5 1.5 1.5 3.0 4.5

Diameter (in) 63” 71” 71” 78” 135”x63”

Total Height (in) 86” 86” 90 ¾” 93” 86”

Grade to Inlet Invert (in) 17 ¾” 16 ½” 16” 14 ¾” 17 ¾”

Grade to Outlet Invert (in) 19 ¾” 20” 19 ½” 18 ½” 21”

Excavation Depth (in) 74” 74 ½” 81” 81” 76”

No. of Aerators 1 1 1 2 3

No. of Filters 30 30 30 30 60

Shipping Weight (lb) 380 420 450 580 920

Inlet Invert* (in) 58” 58” 62 ½” 68” 58”

Outlet Invert* (in) 54 ¾” 54 ½” 59” 64 ¼” 54 ¾”

* From Bottom of Excavation – See Drawing

MULTI-FLO WASTEWATER SYSTEM SPECIFICATIONS

Wastewater Treatment Performance (ANSI/NSF Standard 40 Evaluation)

TEST RESULTS

(Mean Results)

INFLUENT

(mg/L)

EFFLUENT

(mg/L)

REDUCTION

(%)

CBOD

5

150 5 97

TSS 195 5 98

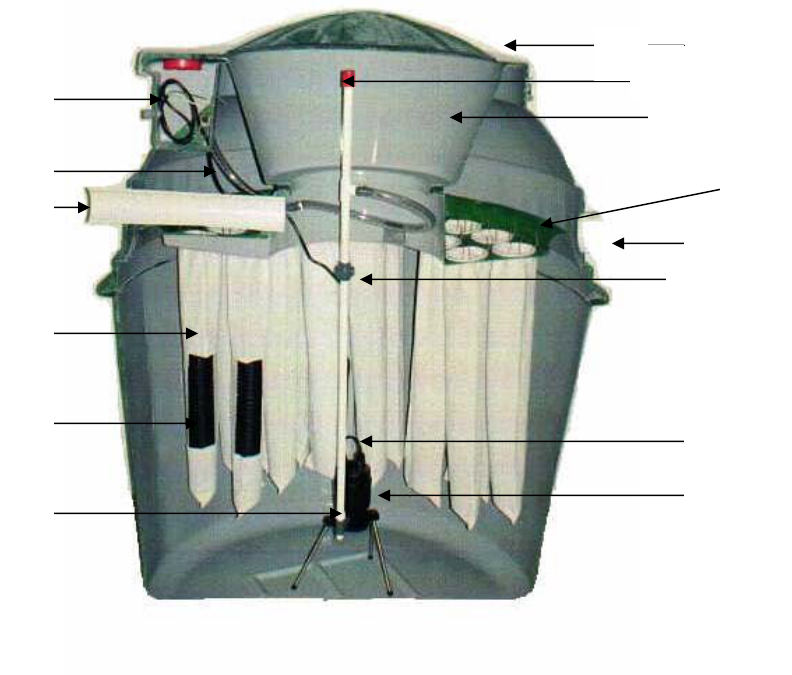

MULTI-FLO COMPONENTS AND SPECIFICATIONS

Item Part No. Description Qty.

1 A5037 Junction Box & Junction Box Cover 1

2 A9510 Air Tubing from sensor 1

3 A5025 Inlet Pipe 1

4 B5017 Filter 30

5 W49104L Expander 30

6 A3016 Air Intake Assy. 1

7 A3008 Access Cover Assy. 1

8 A6517 Primary Alarm Sensor Assy. 1

9 A5029 Surge Bowl 1

10 A6002 Spring Ring Retainers 60

11 A5026 Outlet Pipe 1

12 A9516 ¾” Union 1

13 A6603-4 Aerator Power Cord 1

14 A10031 Aerator 1

1

2

3

4

5

6

7

9

8

10

11

12

13

14

WARRANTY

Consolidated Treatment Systems, Inc., warrants the parts in each aerobic treatment unit to be free

from defects in material and workmanship for a period of two (2) years from date of installation for

treatment of household wastewater when properly registered with the manufacturer. Consolidated

Treatment Systems, Inc., sole obligation under this warranty is as follows: Consolidated Treatment

Systems, Inc., shall fulfill this warranty by repairing or exchanging any component part, FOB Factory,

that shows evidence of defects, provided said component part has been paid for and is returned through an

authorized dealer, transportation prepaid. The warrantee must also notify Consolidated Treatment

Systems, Inc., of the defect complained of. There is no informal dispute settlement mechanism available

under this LIMITED WARRANTY.

No warranty is made as to the field performance of any unit. This LIMITED WARRANTY

applies only to the parts manufactured by Consolidated Treatment Systems, Inc., does not include any

portion of the household plumbing, drainage, or installation of disposal system. Components or

accessories supplied by Consolidated Treatment Systems, Inc., but manufactured by others, are warranted

only to the extent of and by the terms and conditions of the original manufacturer’s warranty. In no event

shall Consolidated Treatment Systems, Inc., be responsible for delay or damages of any kind or character

resulting from, or caused directly or indirectly by, defective components or materials manufactured by

others.

Recommendations for special applications will be based on the best available experience of

Consolidated Treatment Systems, Inc., and published industry information. Such recommendations do

not constitute a warranty of satisfactory performance.

This LIMITED WARRANTY extends to the consumer of the product. As used herein,

“consumer” is defined as the purchaser who first uses the unit or the subsequent user(s) for the first 2

years after its initial installation. It is the first user’s or servicing dealer’s obligation to make known to the

subsequent user(s) the terms and conditions of this warranty.

This warranty is a LIMITED WARRANTY and no claim of any nature shall be made against

Consolidated Treatment Systems, Inc., unless and until the consumer, or his legal representative, notifies

Consolidated Treatment Systems, Inc., in writing of the defect complained of and delivers the product

and/or defective part(s), freight prepaid, to the factory or an authorized service station.

Consolidated Treatment Systems, Inc., reserves the right to revise, change, or modify the

construction and design of the aerobic treatment units for household wastewater, or any component part

or parts thereof, without incurring any obligation to make such changes or modifications in equipment

previously sold. Consolidated Treatment Systems, Inc., also reserves the right, in making replacements of

component parts under this warranty, to furnish a component part which, in its judgment, is equivalent to

the part replaced.

UNDER NO CIRCUMSTANCES WILL CONSOLIDATED TREATMENT SYSTEMS, INC.,

BE RESPONSIBLE TO THE WARRANTEE FOR ANY OTHER INCIDENTAL OR

CONSEQUENTIAL DAMAGES, INCLUDING BUT NOT LIMITED TO LOST PROFITS, LOST

INCOME, LABOR CHANGES, DELAYS IN PRODUCTION AND/OR IDLE PRODUCTION, WHICH

DAMAGES ARE CAUSED BY A DEFECT IN MATERIAL AND/OR WORKMANSHIP IN ITS

PRODUCT OR PARTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES SO THE ABOVE LIMITATION OR

EXCLUSION MAY NOT APPLY TO YOU.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER EXPRESS OR IMPLIED

WARRANTY, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS, AND OF

ANY OTHER OBLIGATION ON THE PART OF CONSOLIDATED TREATMENT SYSTEMS, INC.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. THIS WARRANTY GIVES

YOU SPECIAL LEGAL RIGHTS AND YOU MAY HAVE OTHER RIGHTS, WHICH VARY FROM

STATE TO STATE.

Recommended Prohibitions in an On-Site System

The following is a collaborative effort of wastewater professionals to list items which can cause

on-site treatment systems to operate below their potential. These items are known to have

caused failures of on-site treatment systems and must be considered if the waste generated by

from a particular site will contain them in excessive quantities. Since excessive is a subjective

word, it is highly recommended by NOWRA to share these concerns with a Professional

Engineer or Designer to identify a treatment strategy for the particular needs.

Inert Materials: Plastics, Rubber, Souring Pads, Dental Floss, Cigarette Filters, Bandages,

Hair, Mop Strings, Lint, Rags, Cloth and Towels do not degrade in an on-site treatment

system. Inert Materials will build up solids, and lead to system malfunction, clogging or

increased pump out frequency.

Paper Products: Disposable Diapers, Paper Towels, Baby Wipes, Facial Tissues, Moist Toilet

Paper are not designed to dissolve in an on-site treatment systems. Excessive Amounts

of toilet tissue will not decompose. All can lead to system malfunction, back-up or

increased pump out frequency.

Food Wastes: Do not put Animal Fats & Bones, Grease, Coffee Grounds, Citrus & Mellon

Rinds, Corn Cobs, Egg Shells, down the sink. Garbage disposal use should limited to

waste that cannot be scooped out and thrown in the trash. Spoiled Dairy Products and

Yeasts from home Brewery or baking may cause excessive growth of microbes that do

not degrade sewage.

Medicines: Do not flush Baby Wipes, Lotion, Scented or Quilted Toilet tissue, Female Sanitary

Products, Cotton balls or swabs, Condoms or expired Medicines/Antibiotics. Septic Tank

additives generally do more harm than good. Automatic Disinfection Tablets (blue, clear

or otherwise) will kill the organisms needed to consume waste.

Chemical & Toxins: Kill the microbes necessary for treatment. Paint, Paint Thinner, Solvents,

Volatile Substances, Drain Cleaners, Automatic Fluids, Fuels, Pesticides, Herbicides,

Fertilizers, Metals, Disinfectants, Sanitizers, Bleach, Mop water, Excessive use of

Household chemicals, and Backwash Water Softener regeneration.

Laundry Practices: On-site systems must process the water as it enters the systems. Laundry

should be spread out over the week, not all run at one time. Excessive use of

Detergents, especially those containing bleach, can affect system performance. Liquid

detergents are recommended over powders. Fabric Softener sheets are recommended

over liquid softeners. Bleach should be used sparingly and at half the rate indicated on

the container.

Clear Water Waste: From A/C Discharge lines, Floor Drains, Gutters, Whole House Water

Treatment Systems Sump Pumps can increase the flow to your treatment systems.

These flows can at least disrupt, if not destroy your treatment process.

MULTI~FLO WASTE TREATMENT SYSTEM

GENERAL OPERATIONAL TIPS

UNIT MUST RUN 24 HOURS PER DAY: If leaving residence unoccupied for long periods of time,

contact your servicing dealer. Timers should not be installed unless specifically authorized by

the servicing dealer.

DETERGENTS: Low sudsing detergents should be used. If powdered detergents are used, only the

concentrated forms are recommended. Filler materials used in the “economy size” containers do

not dissolve readily. Below are a few suggestions:

Ultra Cheer with advance color guard powder

Liquid Tide with bleach alternative

Ultra ERA liquid

Arm and Hammer Powder with Bleach

Lanosoft (available thru your dealer)

NEVER USE MORE THAN THE MANUFACTURER’S RECOMMENDED AMOUNT OF DETERGENT: If

excessive sudsing or foaming occurs during laundry, reduce the amount of detergent used to 1/2 of the

recommended amount.

BLEACH: Chlorine bleach should not be used. Oxygen bleaches are recommended. Oxygen

bleaches can be used in any form, liquid, powder, or pellets. Most laundry detergents contain

sodium perborate or bleach which releases boron as it breaks down. Boron has a bactericidal

effect which in excessive quantities could damage your treatment plant so that it is wise to keep

bleach levels to a minimum.

DRAIN CLEANERS: Non-caustic biodegradable drain and toilet bowl cleaners are recommended when

available. DO NOT USE TOILET BOWL CLEANERS SUCH AS 2000 FLUSHED; OR DRAINE

CLEANERS SUCH AS DRANO.

GARBAGE DISPOSAL: Care should be taken not to dispose of grease or fat in the disposal. Food

scraps should be scraped into the garbage container and not flushed down the disposal.

NEVER flush paper towels, newspapers, wrapping paper, feminine articles, and rags into the system.

NEVER allow large, irregular, intermittent or constant volumes of clear water into the system as with a

leaking toilet or faucet. Do not allow the water softener waste discharge line to be connected to

the aerobic system.

WASHING MACHINES are responsible for large volumes of water entering the system all at once. This

surge of water can hydraulically overload the unit and interfere with the smooth operation of the

system. Space washings throughout the week rather than doing several loads in one day.

COOKING OILS AND GREASE are troublemakers. The type of bacteria found in aerobic systems do

not live well in solidified grease. GREASE AND COOKING FATS SHOULD NEVER BE

PLACED DOWN ANY DRAINS.

Under no circumstances should you put any of the following products down the sink, toilets or drains as

they will significantly affect the efficiency of your sewage plant: medicines, cooking oil or melted fat,

motor oils or other car products, garden chemicals, paints, paint thinners and other solvents.

Please read the owners manual and the conditions of the warranty. Your aerobic system is a biological

treatment system designed to achieve a high degree of treatment of domestic sewage. Providing routine

maintenance and following the recommendations of the owner’s manual and your authorized servicing

agent will help insure optimum performance as well eliminate the cost of unnecessary service calls.

Consolidated Treatment Systems, Inc.

1501 Commerce Center Dr.

Franklin, Ohio 45005

PH# 937-746-2727