1

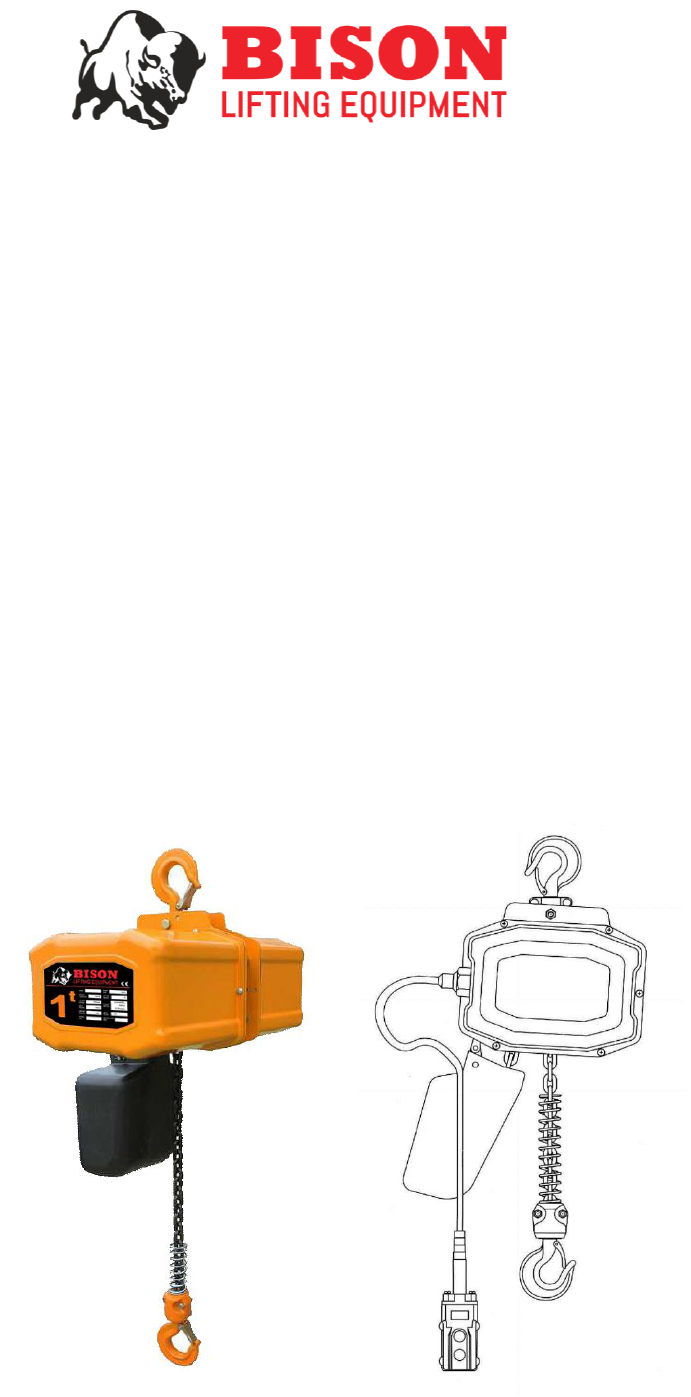

ELECTRIC CHAIN HOIST

OPERATING AND

MAINTENANCE MANUAL

(Capacity: 1/4~5T)

Single Phase/115~230V 60HZ

2

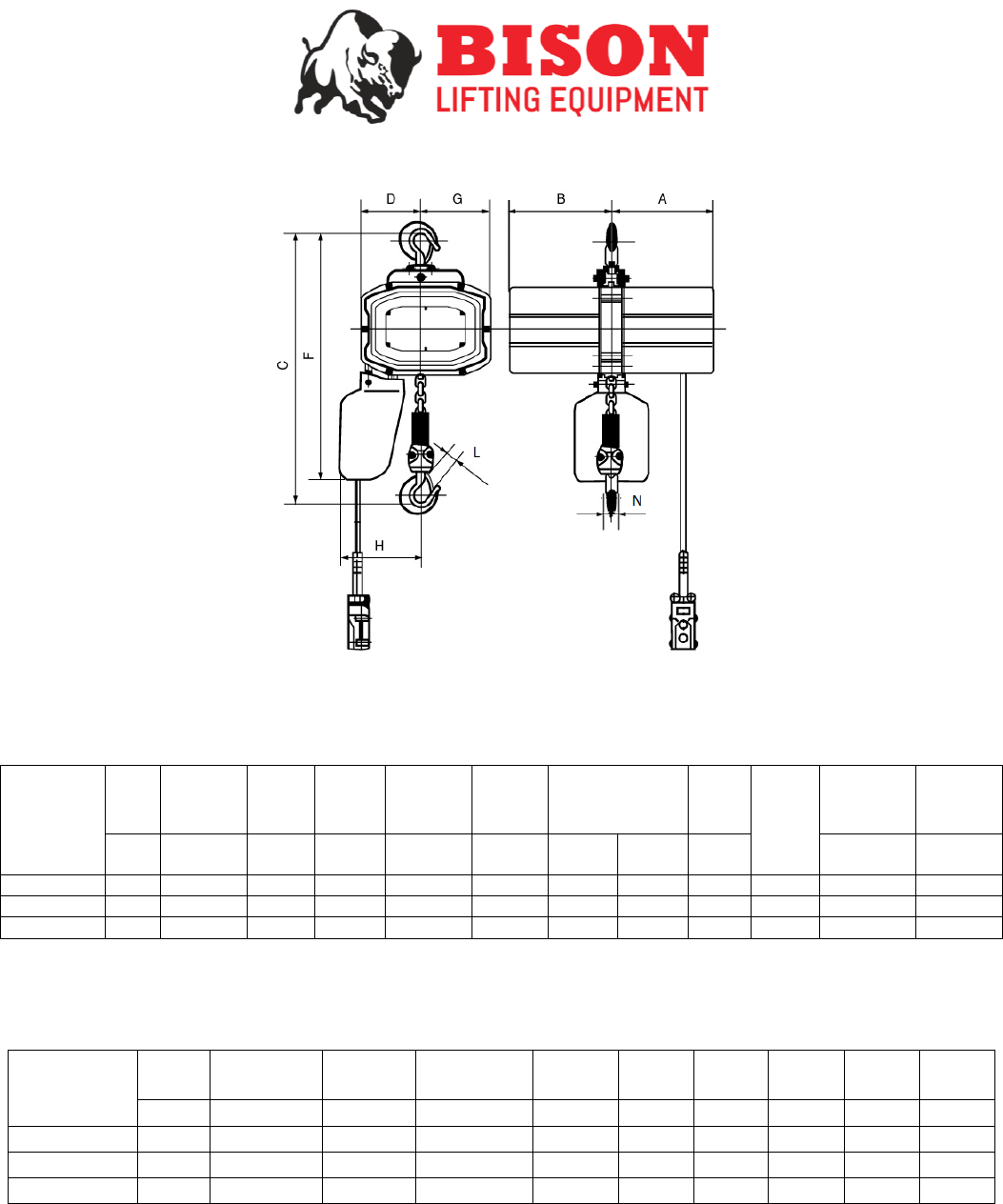

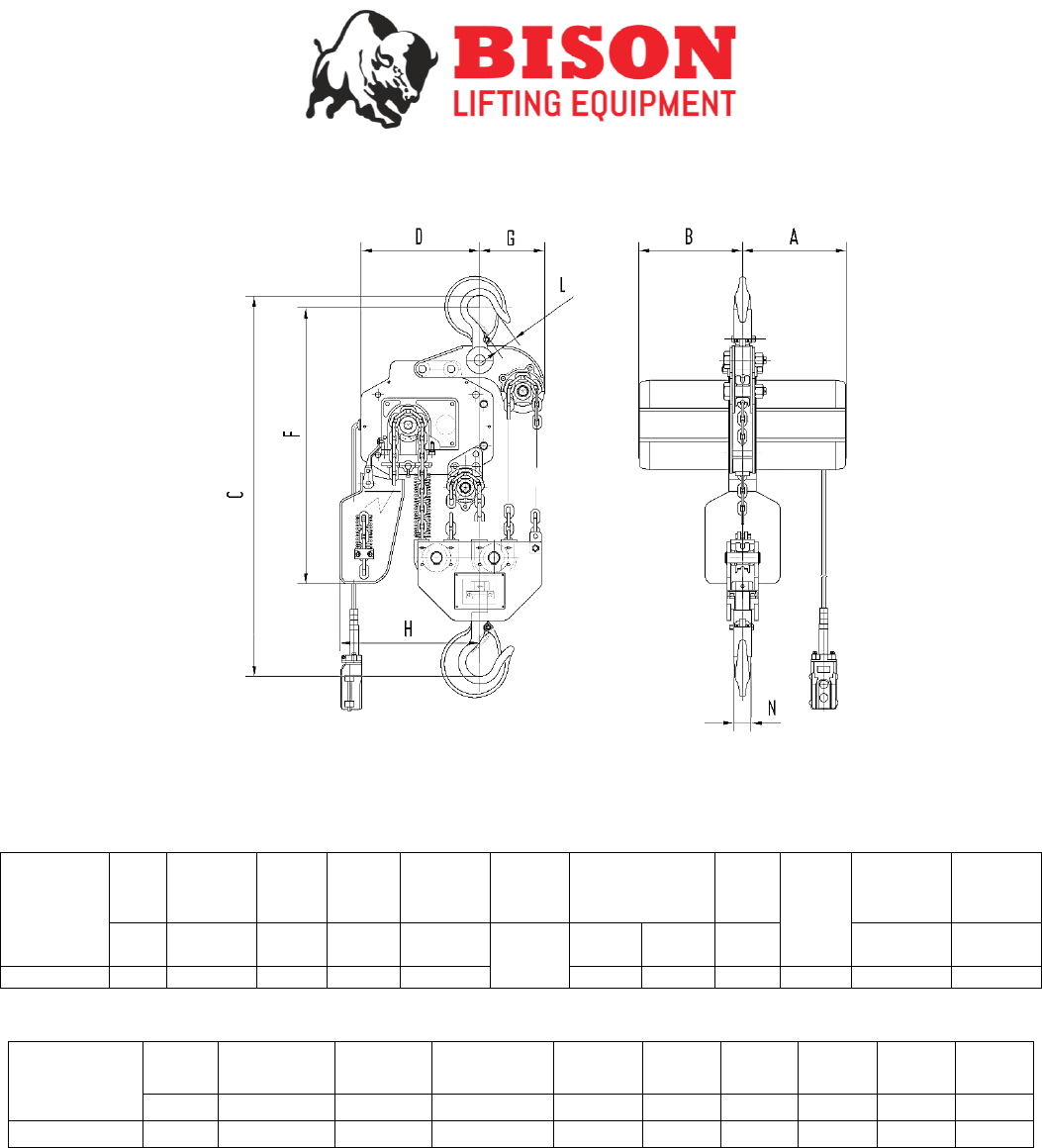

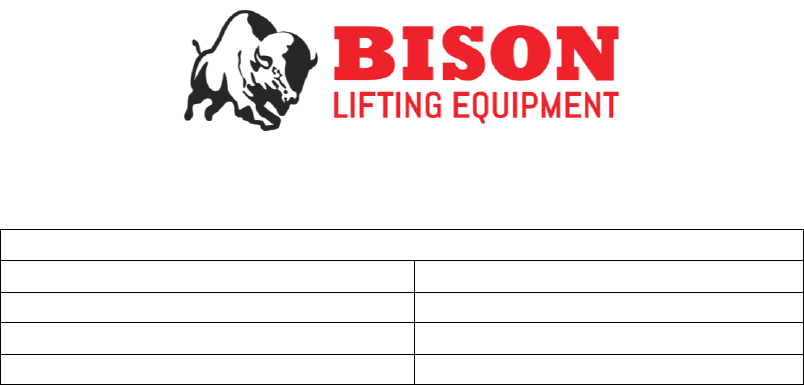

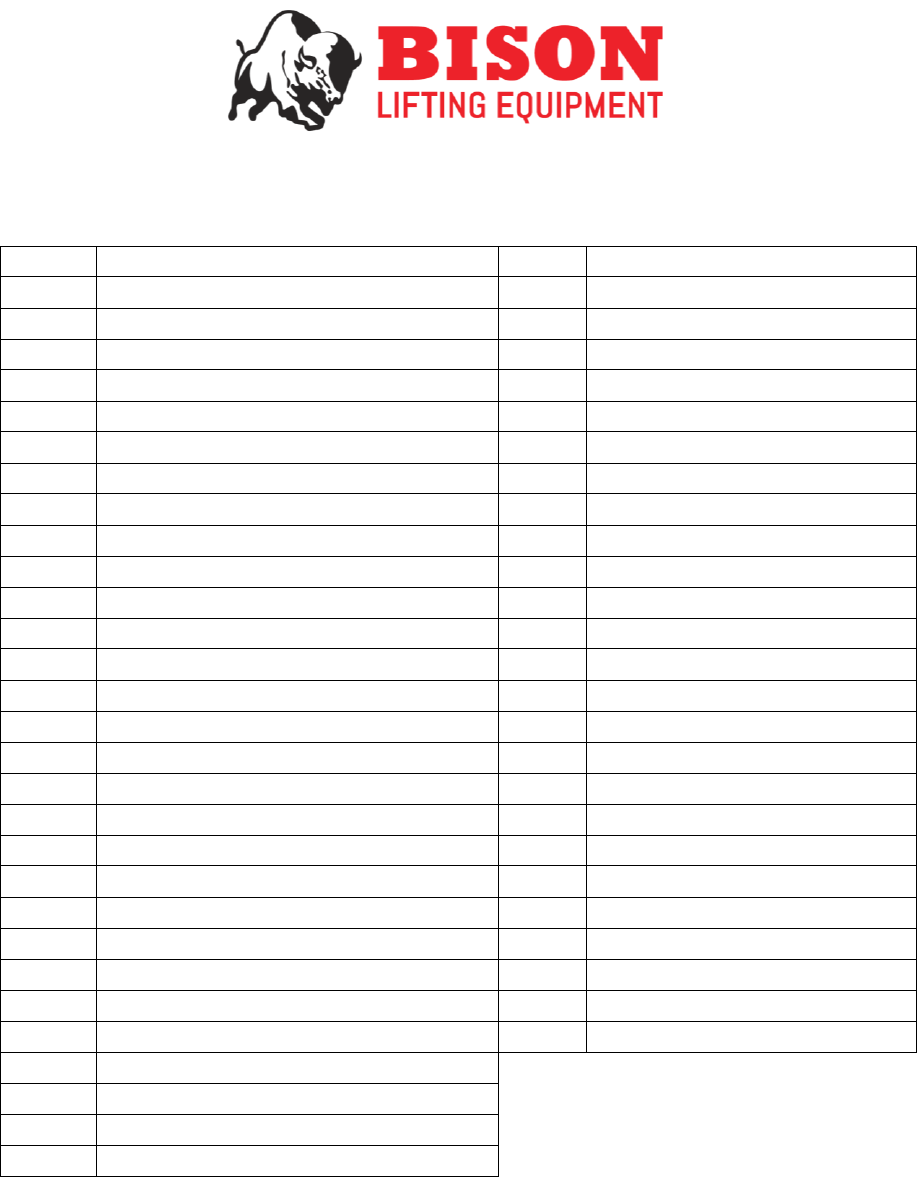

Product Code

Cap.

Head Room

(C)

A

B

G

D

L

F

H

N

Ton

Inches

Inches

Inches

Inches

Inches

Inches

Inches

Inches

Inches

HH-B025

1/4

21.5

10

10

7

6

1.47

22

8

0.73

HH-B05

1/2

21.5

10

10

7

6

1.47

22

8

0.73

HH-B10

1

22.8

10

10

7

6

1.47

24

8

0.73

Product

Code:

Cap.

Standard

Lift

Height

Lifting

Speed

Motor

Output

Power

Supply

Control

Voltage

Rated Current

(amps)

Load

Chain

Size

Chain

Fall

Lines

Pendant

Cord

Length

Total Net

Weight

Tons

Ft.

Ft.

/min

Hp.

Volts (1-

Phase)

Volts

@115v

@230v

mm

Ft.

Lbs.

HH-B025

1/4

20

21

1.3

115/230V

24

9.8

4.9

7.1

1

17

148

HH-B05

1/2

20

21

1.3

115/230V

24

9.8

4.9

7.1

1

17

148

HH-B10

1

20

21

2

115/230V

24

14.2

7.1

7.1

1

17

150

¼, ½, 1 TON

3

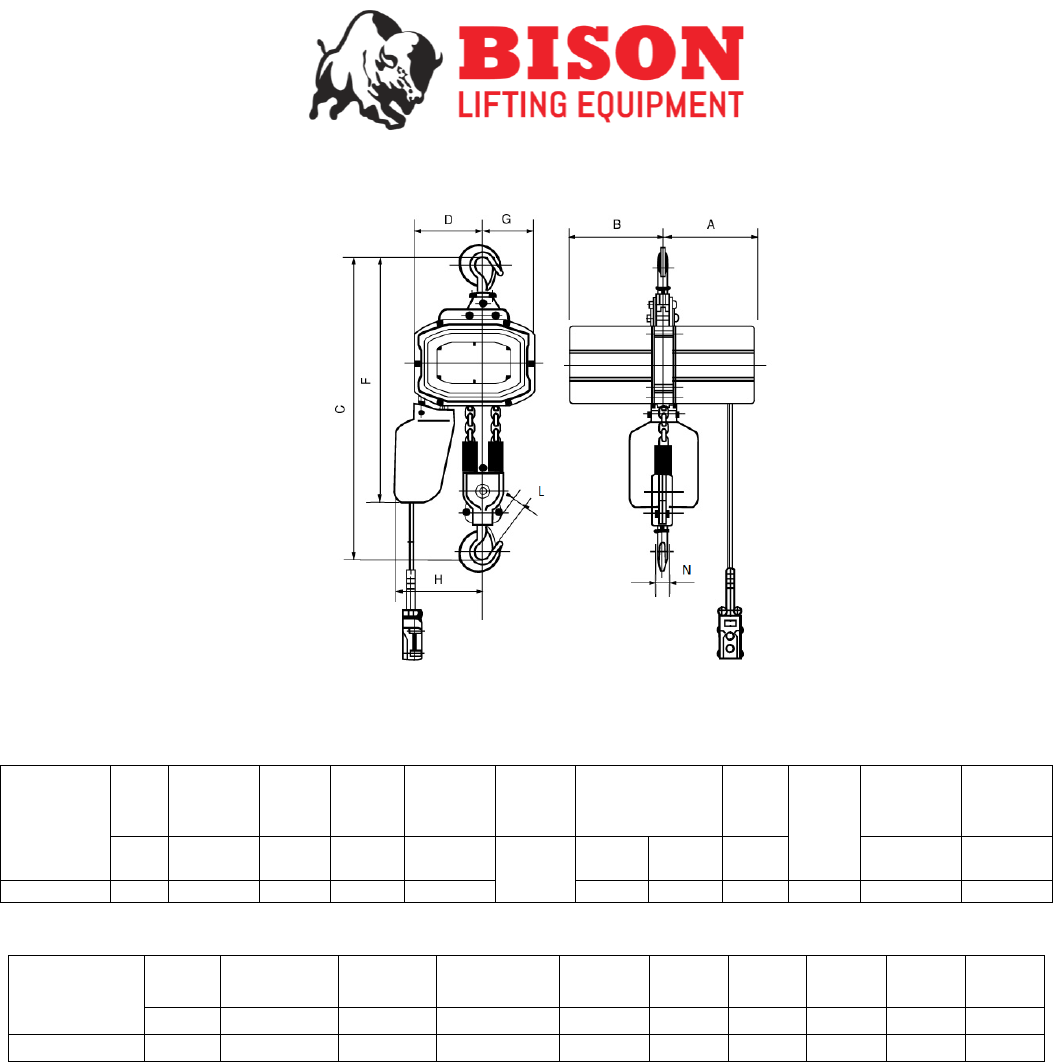

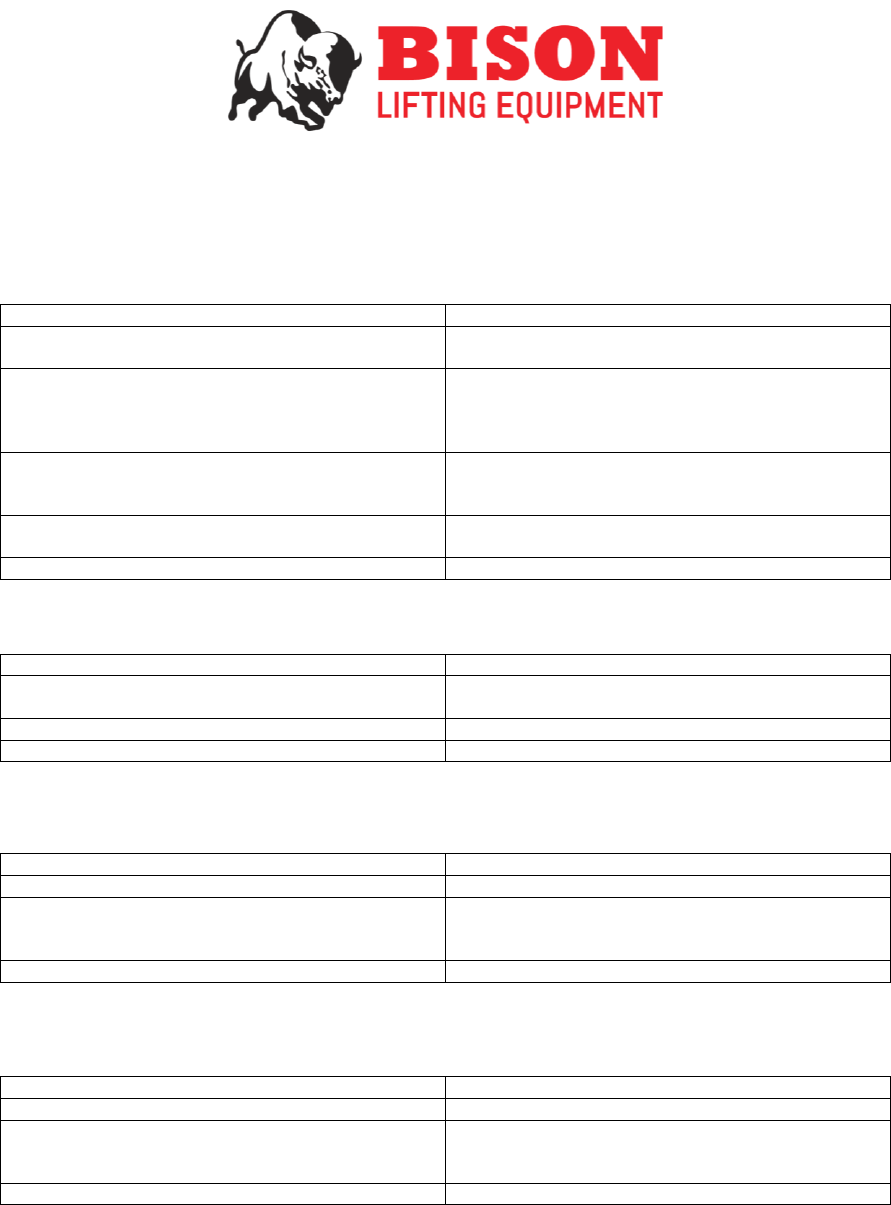

Product

Code:

Cap.

Standard

Lift

Height

Lifting

Speed

Motor

Output

Power

Supply

Control

Voltage

Rated Current

(amps)

Load

Chain

Size

Chain

Fall

Lines

Pendant

Cord

Length

Total Net

Weight

Tons

Ft.

Ft.

/min

Hp.

Volts (1-

Phase)

Volts

@115v

@230v

mm

Ft.

Lbs.

HH-B20

2

20

10.5

2

115/230V

24

14.2

7.1

7.1

2

17

173

Product Code

Cap.

Head Room

(C)

A

B

G

D

L

F

H

N

Ton

Inches

Inches

Inches

Inches

Inches

Inches

Inches

Inches

Inches

HH-B20

2

29.1

10

10

7

5

1.65

26

9

0.83

2 TON

4

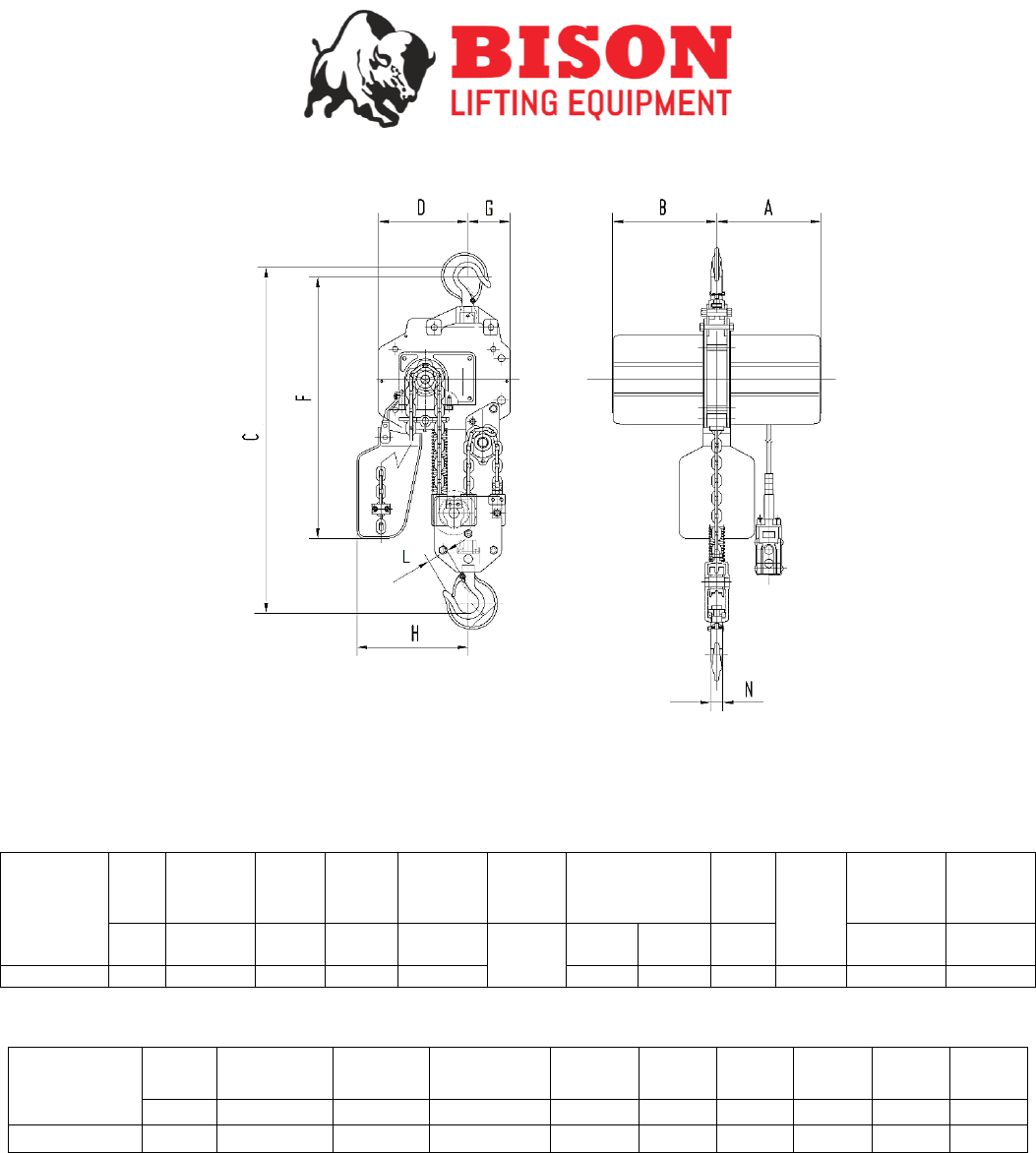

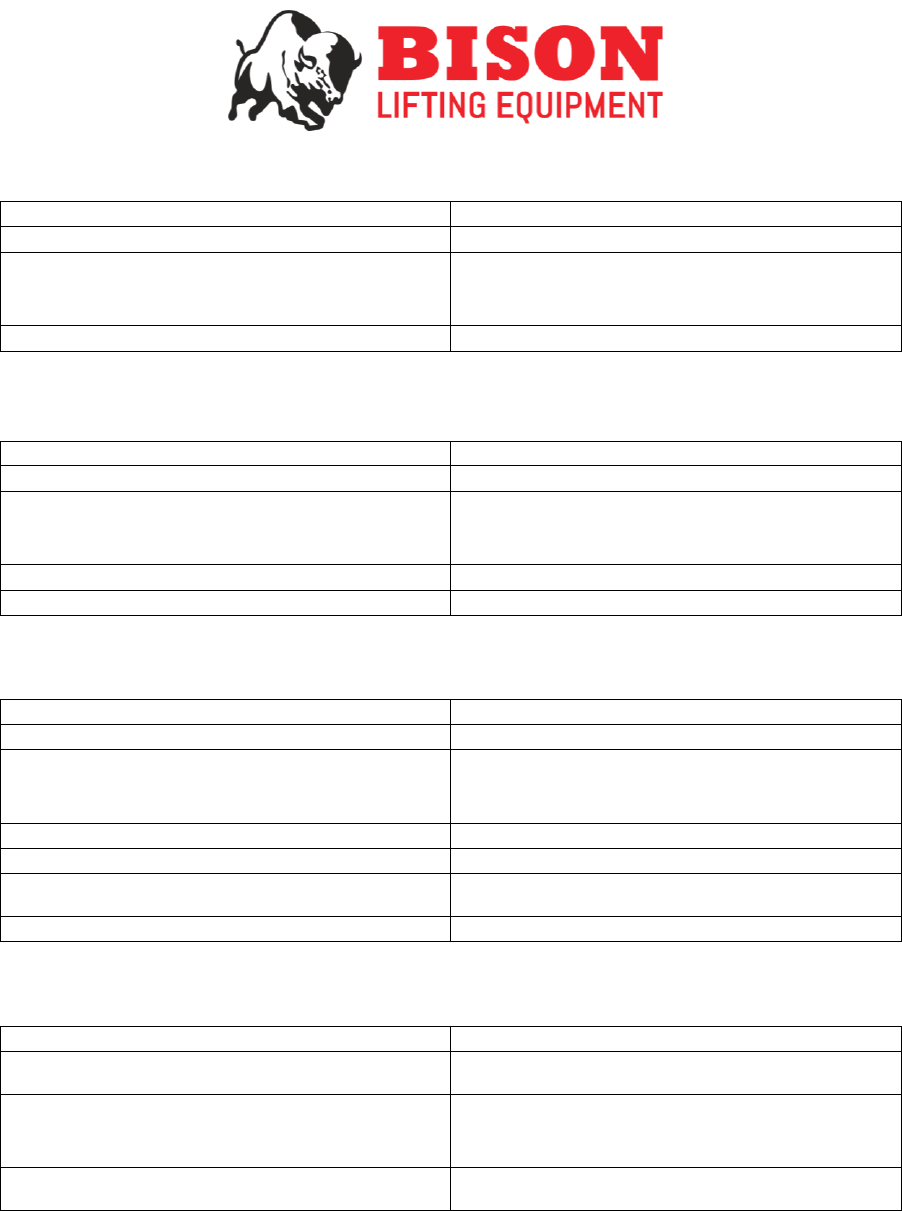

Product

Code:

Cap.

Standard

Lift

Height

Lifting

Speed

Motor

Output

Power

Supply

Control

Voltage

Rated Current

(amps)

Load

Chain

Size

Chain

Fall

Lines

Pendant

Cord

Length

Total Net

Weight

Tons

Ft.

Ft.

/min

Hp.

Volts (1-

Phase)

Volts

@115v

@230v

mm

Ft.

Lbs.

HH-B30

3

20

7

2

115/230V

24

14.2

7.1

7.1

3

17

198

Product Code

Cap.

Head Room

(C)

A

B

G

D

L

F

H

N

Ton

Inches

Inches

Inches

Inches

Inches

Inches

Inches

Inches

Inches

HH-B30

3

31

10

10

4

8

1.69

28

11

0.90

3 TON

5

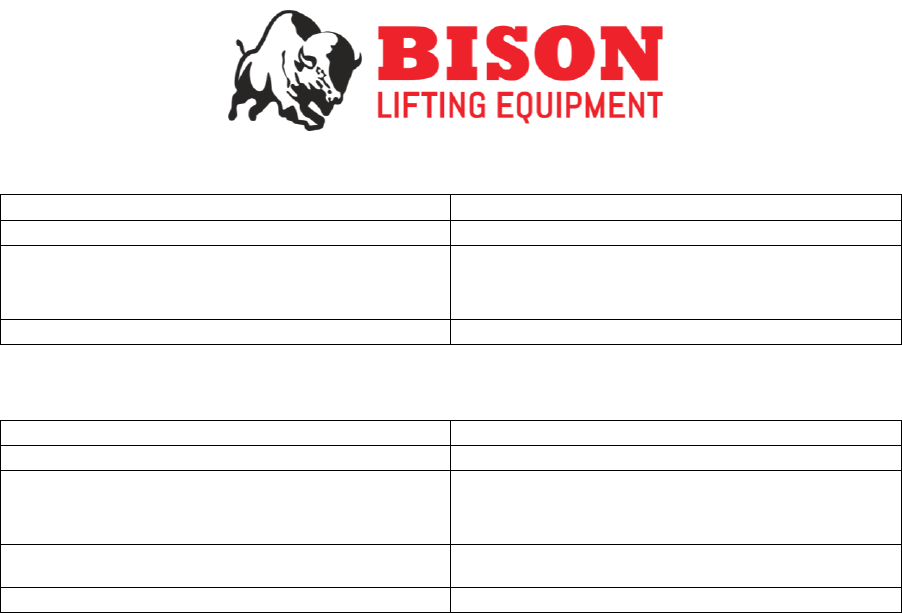

Product

Code:

Cap.

Standard

Lift

Height

Lifting

Speed

Motor

Output

Power

Supply

Control

Voltage

Rated Current

(amps)

Load

Chain

Size

Chain

Fall

Lines

Pendant

Cord

Length

Total Net

Weight

Tons

Ft.

Ft.

/min

Hp.

Volts (1-

Phase)

Volts

@115v

@230v

mm

Ft.

Lbs.

HH-B50

5

20

4.2

2

115/230V

24

14.2

7.1

7.1

5

17

333

Product Code

Cap.

Head Room

(C)

A

B

G

D

L

F

H

N

Ton

Inches

Inches

Inches

Inches

Inches

Inches

Inches

Inches

Inches

HH-B50

5

37

10

10

4

11

2.20

29

13

1.89

5 TON

6

Introduction

This manual is provided by Bison Lifting Equipment covering the safe operation and maintenance procedures for

the Electric Chain Hoist. This manual contains instructions on installation, general operating procedures and

maintenance instructions.

Contents

1. Electric Chain Hoist

2. Operators Manual

3. Warning Page

4. Test Certificate

Set-Up

Pre-Operation Inspection

After opening the crate, carefully inspect the hoist, load chain and chain container for damage that may have occurred

during shipment.

7

Installation

1. Install the hoist to a support structure. It is the user/ owner’s responsibility to ensure the chosen

support structure has the sufficient strength to support the hoist and the rated working load.

2. Connect the hoist to the appropriate power supply.

3. Before using the hoist, apply oil to the chain for easier operation and to prolong the life span.

4. To attach the chain bag/ container run the hoist until it is fully extended (DOWN) and then fasten the

bag/ container to the hoist. Once the bag is securely fastened feed the slack chain (non-load bearing)

into the bag/ container. Then run the hoist in the reverse motion (UP), guiding the slack chain into the

bag/ container (only applicable for those models supplied with the bag/ container)

5. Before proceeding to hoist an application to a dangerous height, test the hoist brake to ensure the

hoist can suspend and hold the weight from a safe height.

8

Operation

Hoisting: Install the hoist to a support structure. It is the user/ owner’s responsibility to ensure the chosen support

structure has the sufficient strength to support the hoist and the rated working load.

Do not attempt to lengthen the load chain in any way.

Do not attempt to repair the hooks as this could weaken them.

General:

1. The friction-clutch is designed to allow the first reduction gear to slip on an excessive overload. An overload

is indicated when the hoist will not raise the load. Also, some clutching noise may be heard if the hoist is

loaded beyond rated capacity. Should this occur, immediately release the raising control to stop operation of

the hoist. At this point, the load should be reduced to the rated hoist capacity or the hoist should be replaced

with one of the proper capacity. When the excessive load is removed, normal hoist operation is

automatically restored. [CAUTION: the friction clutch is susceptible to overheating and wear when slipped

for extended periods. Under no circumstance should the protector be allowed to slip for more than a few

seconds.]

2. Before picking up a load, check to see that the hoist is directly overhead. Avoid off-center loading of any

kind.

3. Take up a slack load chain carefully and start hoisting load gently to avoid shock and jerking of the load

chain. If there is any evidence of overloading, immediately lower the load and remove the excess load.

4. Do not allow the load to swing or twist while hoisting.

5. Do not allow the load to bear against the hook latch or the tip of hook.

6. Make sure the pendant cord is straight and is not tangled in the chain. Be careful not to snag the cord on

any sharp edges or objects.

7. When handling material that is being immersed in water, baths or any liquid, use a chain sling to prevent the

hook block from having to be submerged- this will stop any liquid from penetrating the bearing.

Precautions

- During overhead lifting operations, personnel should NOT stand beneath the suspended load.

- Prevent the load chain from dragging over sharp edges or corners.

- Be cautious of having fingers caught in the mechanisms.

- Do NOT leave a suspended load unattended.

- Do NOT attempt to lift people.

- Do NOT use the load chain to basket or choke a load.

- Do NOT drag or drop the hoist.

- Do NOT put the bottom hook through the loop of the chain. (only applicable on 2; 3 and 5-fall models)

9

Maintenance

The inspection procedure advised is based on ANSI/ASME B30.16. The following definitions are from

ANSI/ASME B30.16.

Inspection Classification

The inspection procedure is divided into two general grades based upon the intervals at which inspection

should be performed.

Hoist Service Duty

Duty

Average % of rated capacity

Normal

0 to 33%

Heavy

33 to 67%

Severe

67 to 100%

Special

Special Conditions

Frequent: Operators are to make visual inspections as often as required.

- Normal Duty Service – monthly

- Heavy Duty Service – weekly to monthly

- Severe Duty Service – daily to weekly

- Special Duty Service – recommend being inspected by a qualified individual before and after

each operation.

Periodic: Qualified individuals are to make visual inspections as often as required.

- Normal Duty Service – annually

- Heavy Duty Service – semiannually (twice a year)

- Severe Duty Service – quarterly

- Special Duty Service – recommend being inspected by a qualified individual before and after

each operation.

Frequent Inspection

The following is required to be inspected frequently:

- All functional operating mechanisms.

- Functionality of limit switch

- Hoist braking system

- Hooks in accordance with ANSI/ASME B30.10

- Hook latches

- Load chain

- Load chain reeving

10

Periodic Inspection

The following is required to be inspected periodically:

ANSI/ASME B30.16 requires all hoists subject to disassembly of load suspension parts, to undergo a load test

after re-assembly to pass full inspection.

Requirements of frequent inspection:

- Evidence of loose bolts, nuts, or rivets.

- Evidence of wear, corrosion, cracks, or distortion to parts such as load blocks, suspension housing, chain

attachments, clevises, coupling, suspension bolts, shafts, gears, bearings, pins and rollers.

- Evidence of damage to bottom block assembly.

- Evidence of excessive wear on motor or load brake.

- Evidence of damage of supporting structure/ trolley.

- Direction labels on pendant control stations.

- Warning label properly attached to the hoist.

- Load chain end connections.

- Evidence of wear, cracks or stretching on the load chain.

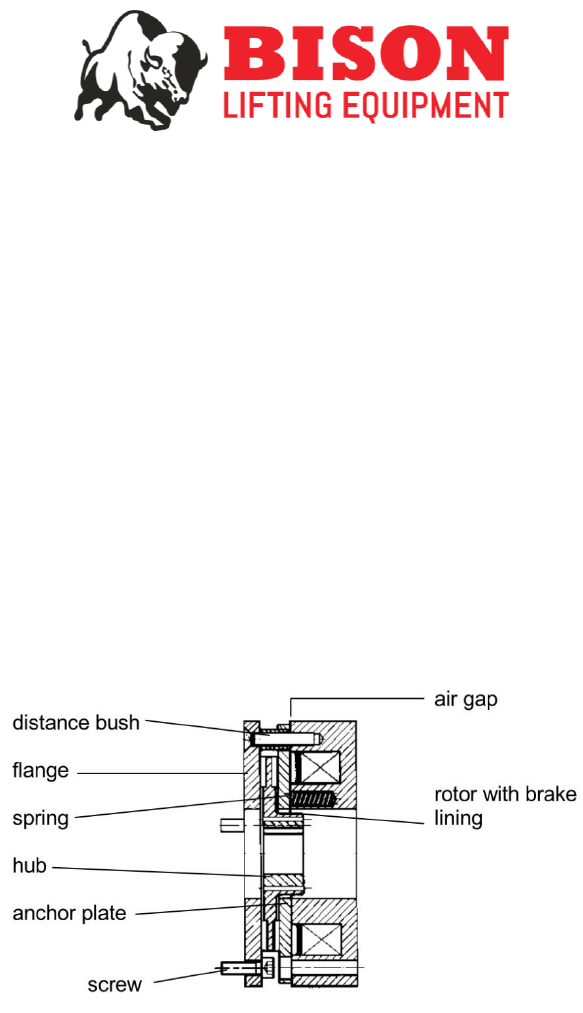

Brake Adjustment

• Brake Device: Should be checked and cleared of all dust and oil every three months. The air gap

should be no smaller than 0.3mm and no larger than 0.5mm. If the brake will not adjust, the brake

should be replaced before further damage or failure of the hoist occurs.

11

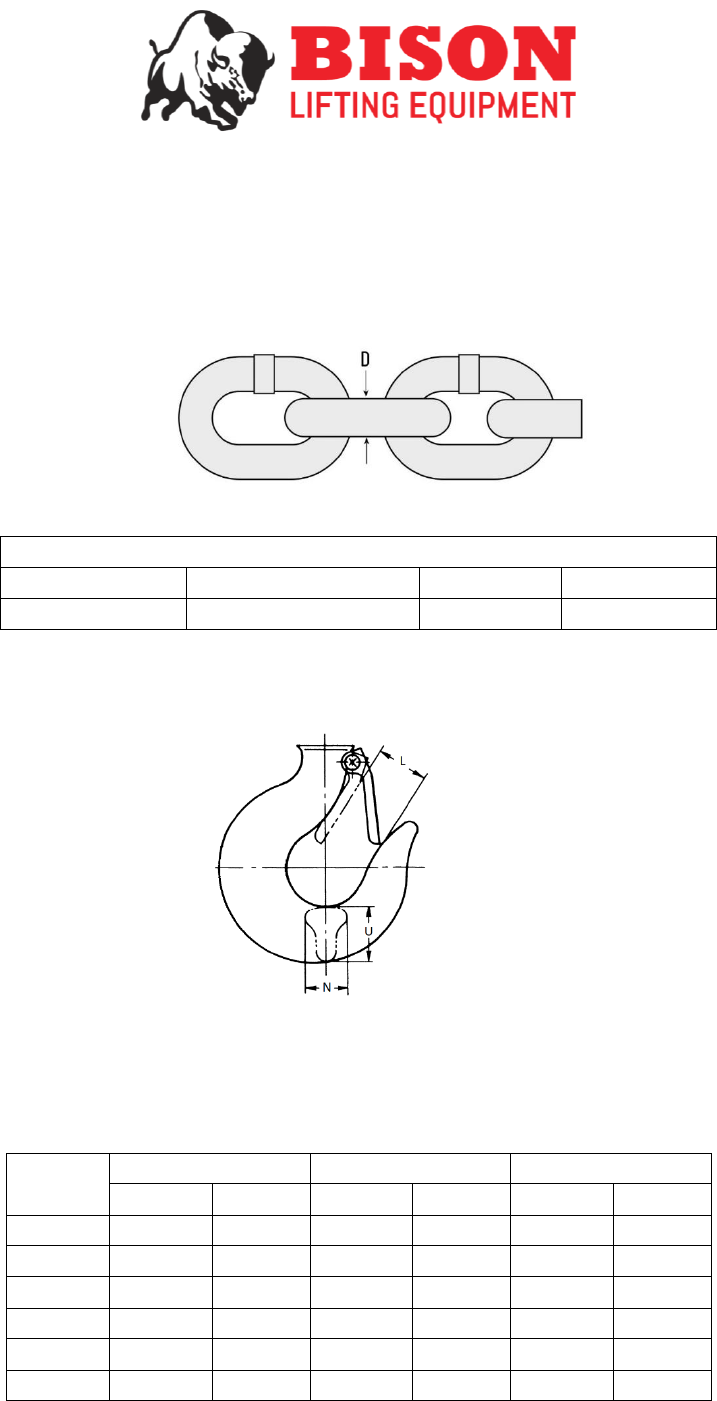

Chain Inspection

Inspect the chain for excessive wear, corrosion, or any cracks. If the load chain shows any of these signs, the

chain must be replaced immediately.

Using a Metric Vernier caliper, measure the distance of D to assess whether the wear of the load chain is within

the allowed tolerance. Refer to chart below.

It is vital that the chain be lubricated after every inspection.

Hook Inspections

Inspect the hook for damage such as cracks, bends and excessive wear. While inspecting the hook, measure

points L, N and U. Refer to the table below to judge whether the measurement is within the tolerance or not. If

the measurement reads the value in the “Replace” column or lower, the hook needs to be replaced immediately.

Ensure the hook has a safety latch and that it is not bent or damaged that could result in an application to slip

off or out the hook.

Load Chain Wear

Hoist Capacities:

Inspection link intervals

Standard Size

Tolerance limit

¼, ½, 1, 2, 3, 5 Ton

5

7.1mm

6.4mm

Capacity:

Size of: L (inches)

Size of: U (inches)

Size of: N (inches)

Standard

Replace:

Standard

Replace:

Standard

Replace:

¼ T

1

1.47

1.10

1.03

0.73

0.65

½ T

1

1.47

1.10

1.03

0.73

0.65

1 T

1

1.47

1.10

1.03

0.73

0.65

2 T

1

1.65

1.30

1.22

0.83

0.75

3 T

2

1.69

1.37

1.28

0.90

0.83

5 T

2

2.20

2.68

2.60

1.89

1.81

12

Contactor Inspections

Recommended Contactor Replacement

Frequency of Jogging

Replace contactor after: (Starts)

Jogging is rare

1,000,000

during 25% of operations

500,000

During 50% or more or operations

200,000

Refer to the chart above for the recommend work rating of the hoist’s contactors. (Jogging: when the pendant

control buttons are pressed quickly and repetitively in to move the hook in small increments)

Records

Reports of hoist maintenance and inspections should be kept on record for reference and

maintenance scheduling.

General Maintenance:

• Gearing should be cleaned, and grease lubricated at least twice a year.

• Hooks: should be checked periodically for deformation and wear. Hooks should be replaced

immediately if signs of excessive rust, wear, cracks or deformation are shown.

• Ensure the load chain is kept straight and untangled when storing to prevent the chain from kinking or

twisting.

• Any hoists used out-doors should be covered up or stored in a clean dry environment when not in use.

13

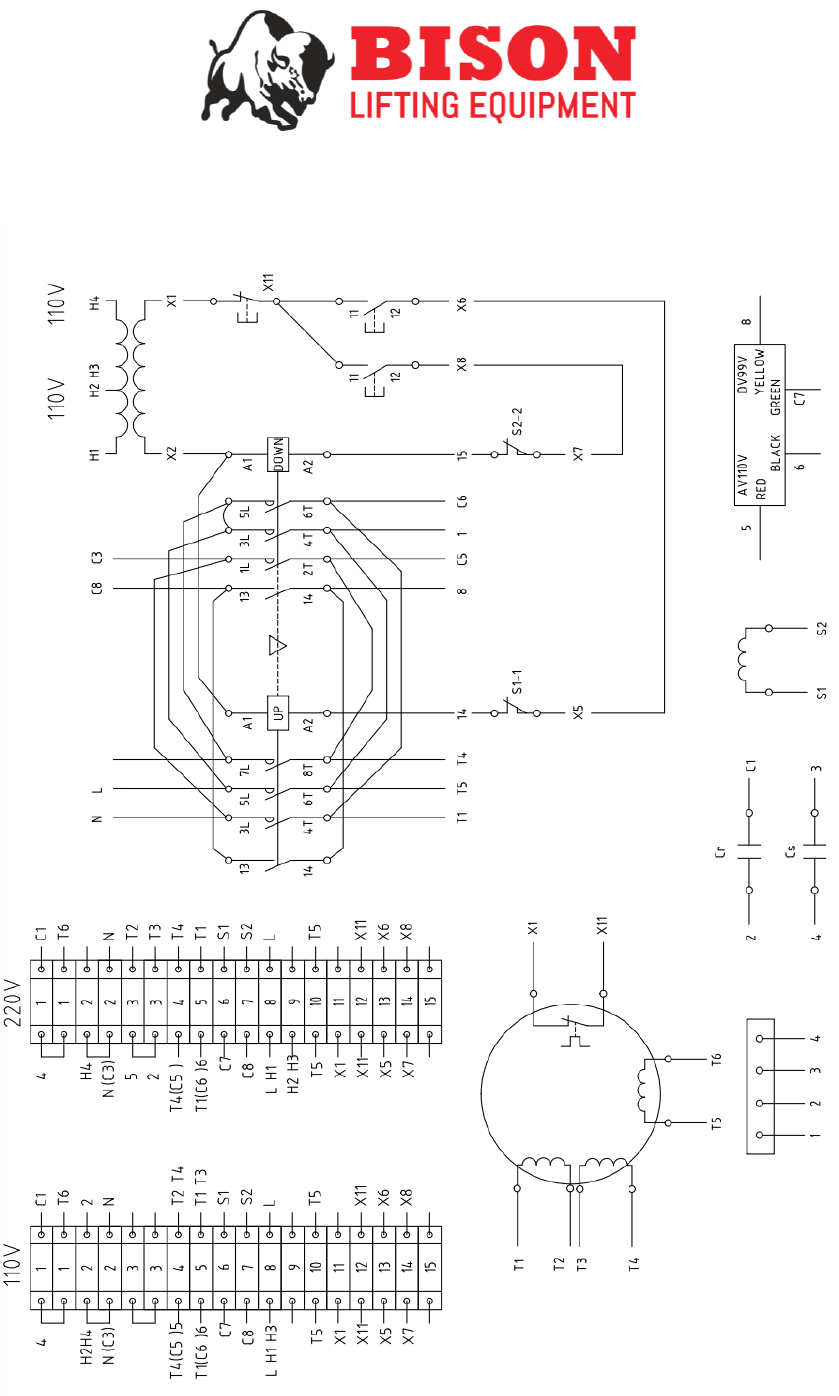

Troubleshooting

HOIST NOT RESPONDING TO PUSHBUTTON/ PENDANT CONTROLLER

INCORRECT HOISTING DIRECTIONS

HOOK LOWERS BUT WILL NOT RAISE

HOOK RAISES BUT WILL NOT LOWER

Possible Cause

Remedy

No voltage at hoist-main line or emergency stop is

not released; fuse blown, or circuit breaker tripped

Release emergency stop; replace fuse or reset

breaker

Open or shorted wiring in the transformer; loose

connection or broken wire in circuit; mechanical

binding in contactor relay; pendant station

(pushbutton) contacts not closing or opening

Using a multimeter, test for electrical continuity and

repair or replace defective part.

Brake not releasing

Check input & output voltage of brake rectifier, check

brake airgap settings, if necessary, replace rectifier

and or brake coil.

Wrong voltage or frequency.

Be sure power supply corresponds to the hoists

required electrical specifications

Excessive overload

Reduce hoist load.

Possible Cause

Remedy

Connections reversed at either the control station or

terminal block.

Check connections with the wiring diagram

Possible Cause

Remedy

Excessive Load

Reduce Hoist Load

Loose connection or broken wire in the circuit;

pendant station contacts not being made; Upper limit

switch contacts are open.

Check the connections and contacts for sticking or

damage.

Start Capacitor damage

Replace the running capacitor

Possible Cause

Remedy

Excessive Load

Reduce Hoist Load

Loose connection or broken wire in the circuit;

pendant station contacts not being made; Upper limit

switch contacts are open.

Check the connections and contacts for sticking or

damage.

Start Capacitor damage

Replace the running capacitor

14

HOOK DOES NOT STOP PROMPTLY

HOIST OPERATES SLUGGISHLY

HOIST MOTOR OVERHEATS

HOIST IS NOISY

Possible Cause

Remedy

Brake Slipping

Check brake mechanism

Excessive Load

Reduce hoist load

Incorrect wiring of brake leads.

Check connectors with wiring diagram

Possible Cause

Remedy

Excessive load

Reduce hoist load

Low Voltage

Correct low voltage condition

Brake is not fully releasing

Check brake mechanism & air gap

Damaged run capacitor

Replace the damaged run capacitor

Possible Cause

Remedy

Excessive load

Reduce loading to the capacity of hoist

Low Voltage

Correct low voltage condition

Brake is not fully releasing

Check brake mechanism & air gap

Frequent jogging

Prevent frequent jogging

Excessive run cycles

Only operate the hoist within the duty cycle of the

motor: 40% ED

Unsuitable ambient temperature

Hoist must be operated in conditions no hotter 104°F

Possible Cause

Remedy

Noisy gears- excessive ear of gear; insufficient

quantity of grease.

Inspect gears. Replace gears or re-grease if

necessary

Incorrect incoming power supply

Check the voltage at the hoist for voltage

consistency, voltage spikes or drops can cause

damage to the hoist.

Noisy chain -damaged pocket wheel, excessive wear.

Twisted chain

Inspect the chain and pocket wheels for excessive

damage. Straighten the chain

15

LOAD CHAIN JUMPS ON SHEAVE

ELECTRICAL SHOCK WHEN TOUCHING THE HOOK OR CHAIN

Possible Cause

Remedy

Worn Chain

Inspect chain wear

Worn chain pocket wheel or sheaves

Replace parts

Twisted or kinked chain

Straighten and line up chain links

Possible Cause

Remedy

No grounding

Ground the grounding line in the power supply

Incorrect grounding

Check grounding terminal

Live part contacting to grounded part

Check electrical wiring and correct grounding if

necessary

Capacitor damage

Replace capacitor

16

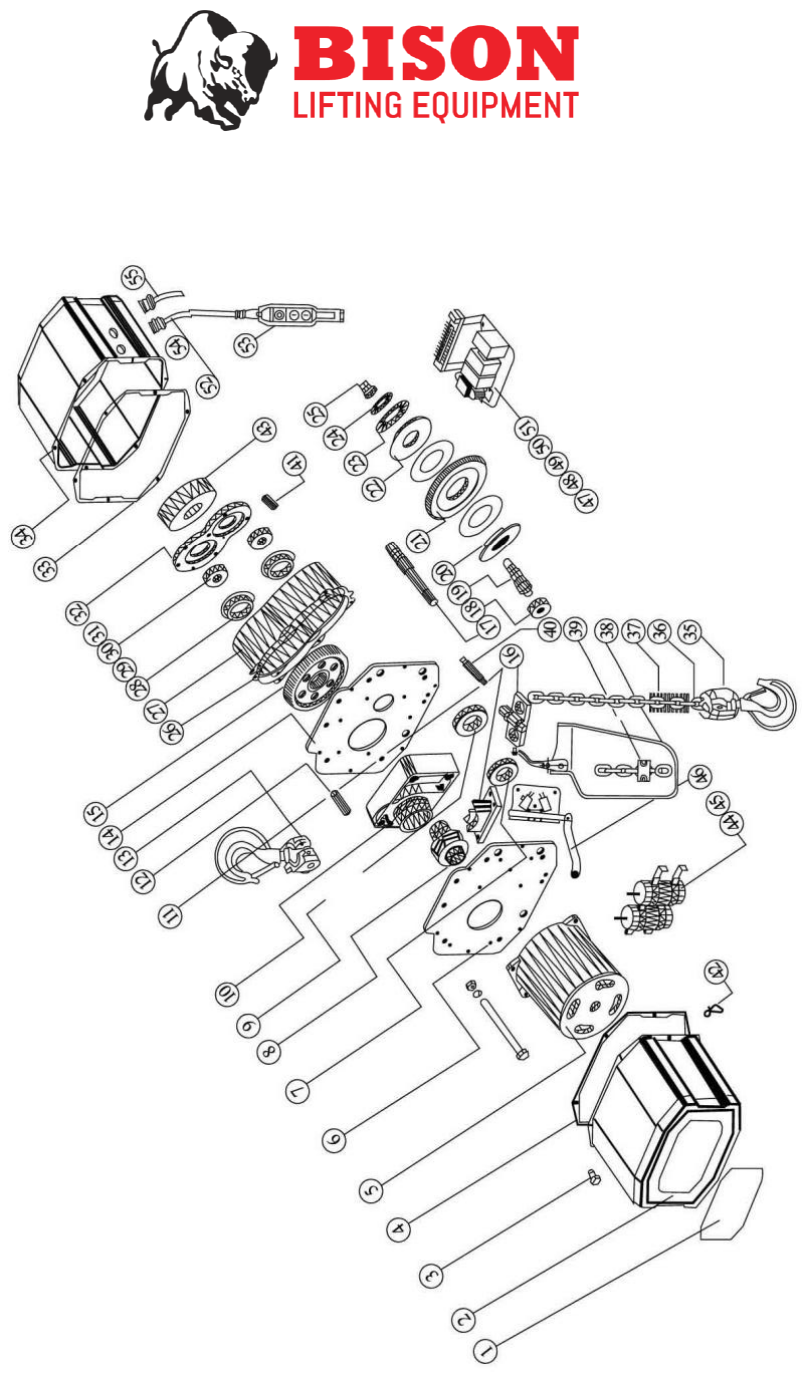

Electric Chain Hoist Drawings (¼T, ½T, 1T)

17

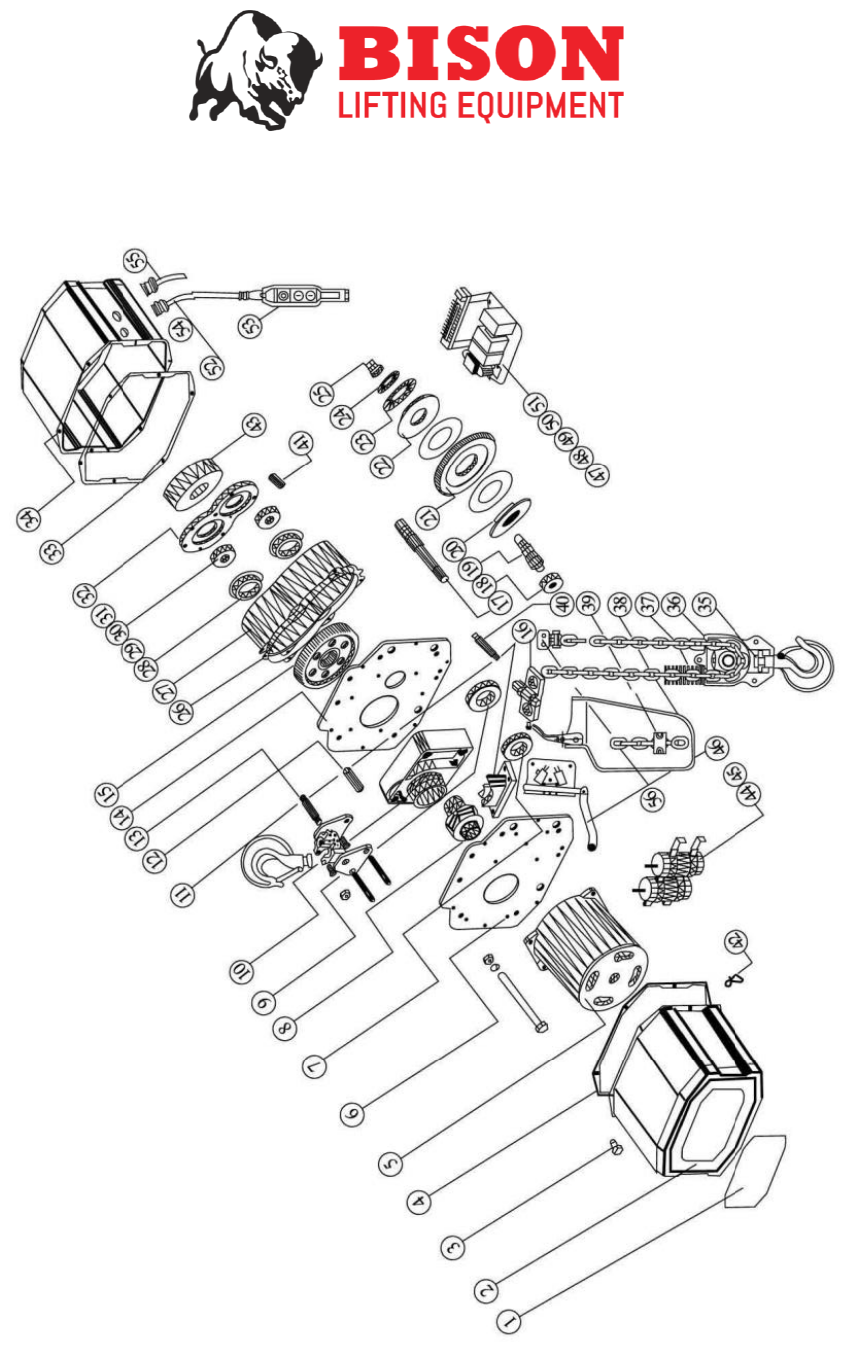

Electric Chain Hoist Drawings (2T)

18

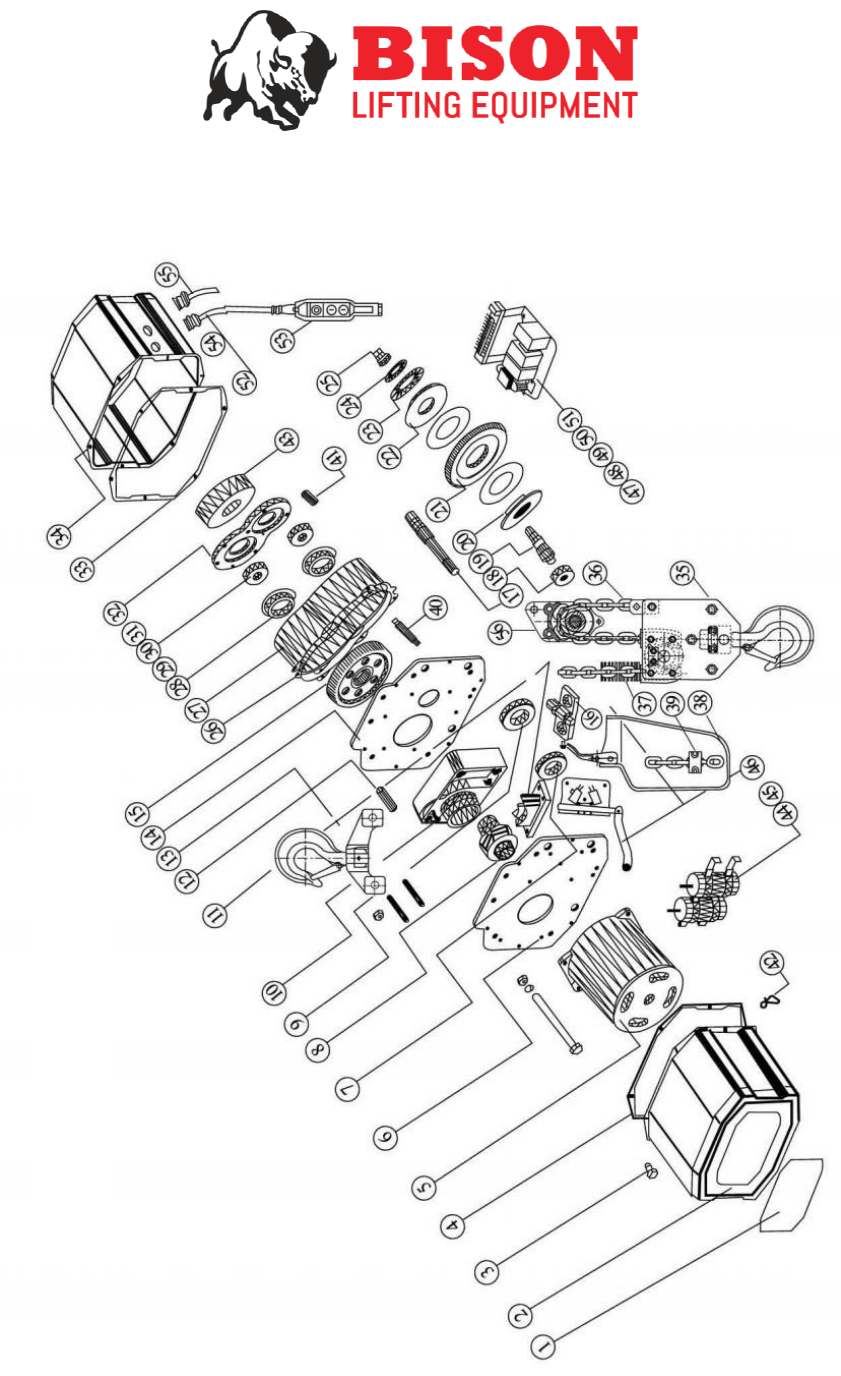

Electric Chain Hoist Drawings (3T)

19

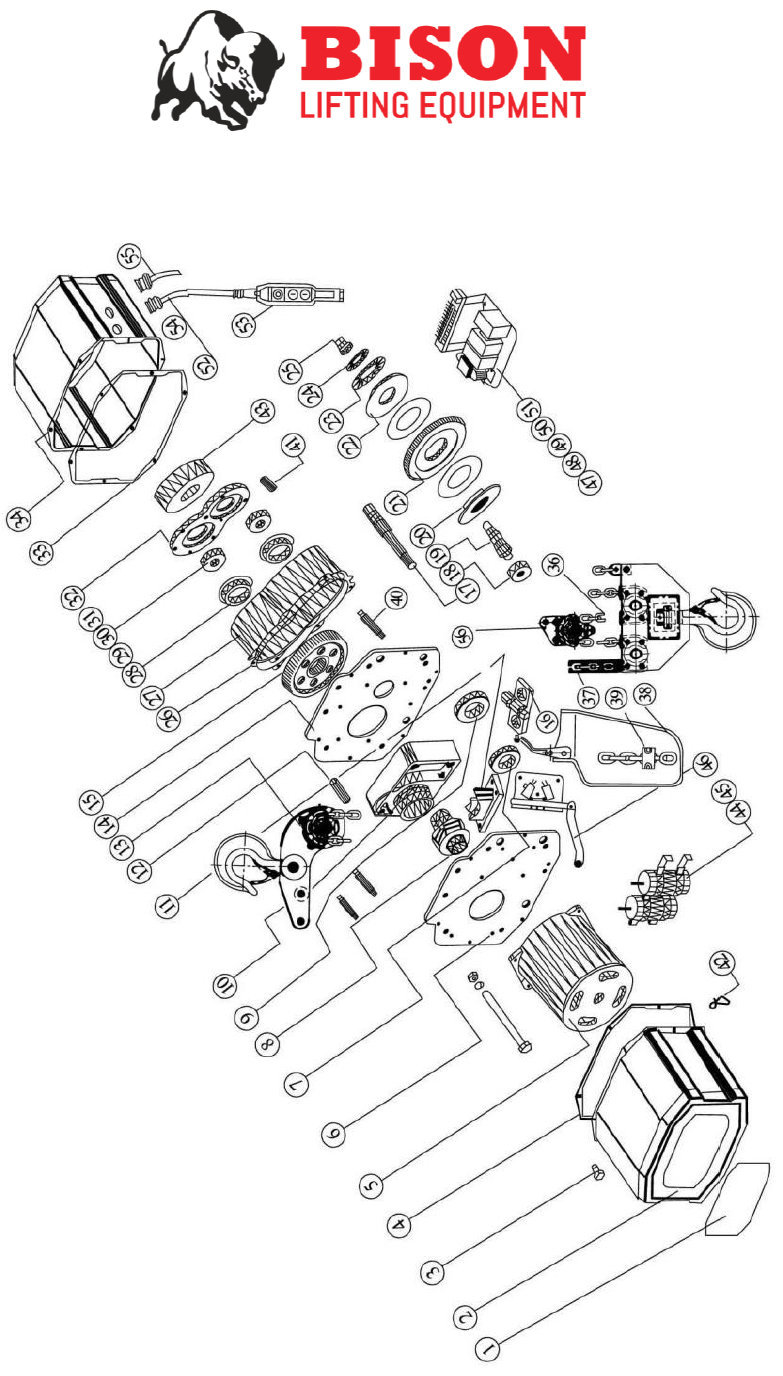

Electric Chain Hoist Drawings (5T)

20

Parts List

1

Name plate

31

Bearing

2

Cover

32

Coupling Plate

3

Hex Bolt

33

Hoist Gearbox Cover Gasket

4

Hoist Motor Cover Gasket

34

Cover

5

Motor

35

Bottom Hook Subassembly

6

Motor Mounting Plate

36

Load Chain

7

Bearing

37

Spring Buffer

8

Sprocket Wheel / Pocket Wheel

38

Chain Container

9

Bearing

39

Load Chain End Stop Clamp

10

Sprocket Wheel Housing

40

Connecting Pin

11

Chain Guide

41

Gearbox Housing Bolt

12

Conduit

42

Pendant Cord Strain Relief Clip

13

Top Hook Set Subassembly

43

Arrester Assembly

14

Gearbox Mounting Plate

44

Start Capacitor

15

Spline Gear

45

Run Capacitor

16

Limit Switch Actuator

46

Limit Switch Assembly

17

Driving Gear Shaft

47

Contactors

18

Bearing

48

Transformer

19

Gear Pin

49

Electrical Terminal

20

Clutch Set Plate

50

Brake Rectifier

21

Drive Gear Subassembly

51

Electrical Panel

22

Spacer

52

Control Cord

23

Spring Disk

53

Pendant Controller

24

Spring Seat

54

Cord Gland

25

Adjustable Nut

55

Power Cord

26

Gear Housing Spacer

56

Chain Fall Suspender

27

Gear Housing

28

Bearing Set A

29

Bearing Set B

30

Bearing

21

Electric Chain Hoist (Stop + Up + Down)

22